+

+

In collaboration with Hawaiian Electrical Company (HECO), a major utility company in the state of Hawai’i, Oceanit is currently evaluating the use of HeatX to protect shell-and-tube heat exchangers from biofouling and corrosion. HECO uses seawater as a secondary source of coolant in their shell and tube chillers for removing heat from hot liquids exiting the power generation turbine.

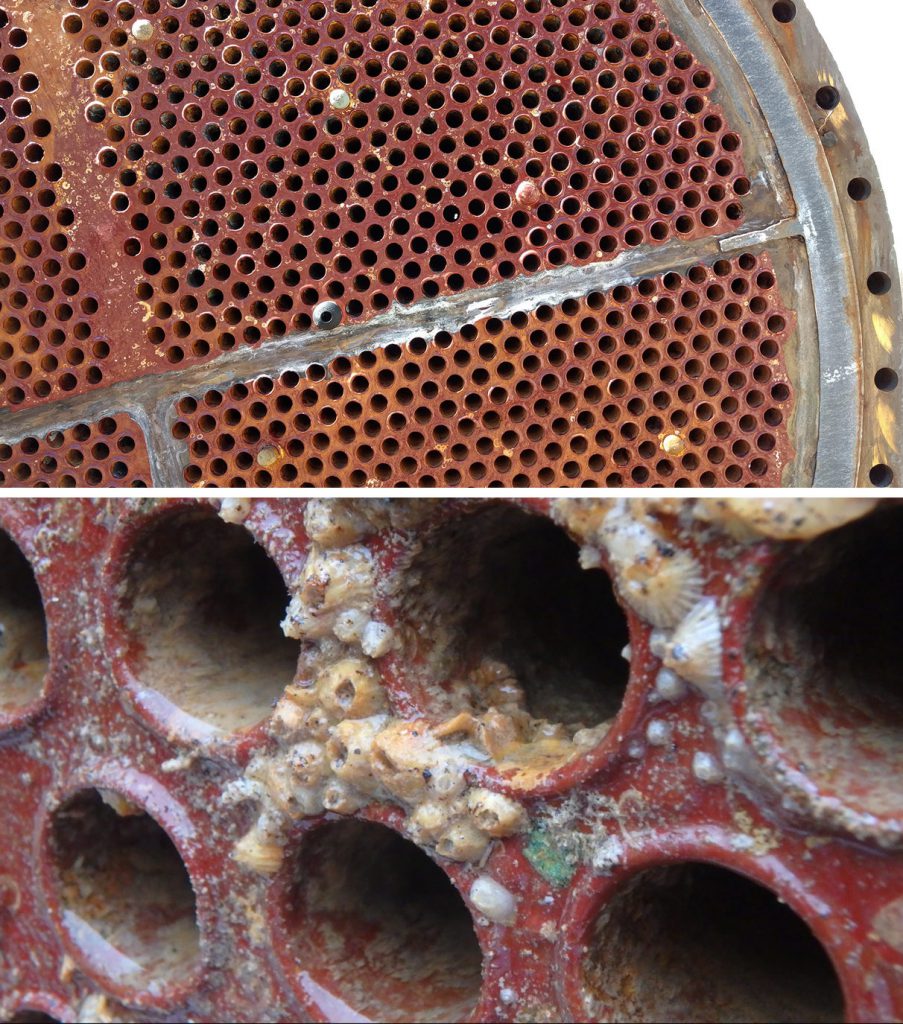

Utilization of seawater for cooling introduces the major challenge of barnacle growth and fouling that can plug the inner tubes of the heat exchangers and results in significant reduction in the heat transfer efficiency. In addition, most of the metallic components which are exposed to seawater are susceptible to high levels of corrosion and needs to be addressed regularly. HECO estimates that on an average every 6 months most of the exchangers used in the plant undergo thorough cleaning, and biofouling can occur in as little as 30 days.

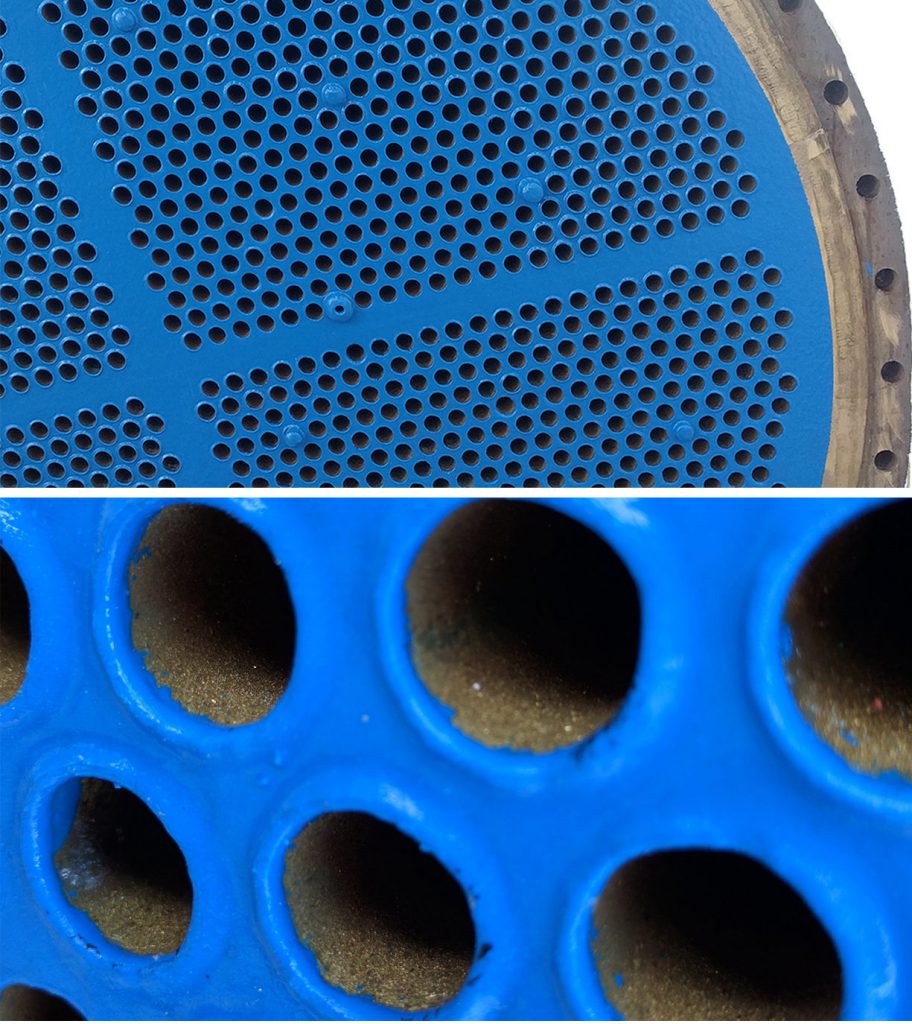

In this effort, Oceanit collaborated with HECO to apply HeatX on-site to refurbish an exchanger containing approximately 1500 3⁄4” diameter, copper-nickel tubes of 20’ length. Treatment, cleaning, inspection and qualification were completed with only requiring 2 weeks of non-operation. Due to the extreme low surface energy of the HeatX Treatment, barnacle adhesion will be minimized within the tubes, while the carbon steel tube sheets can be protected against corrosion due to immersion within the seawater environment.

Figure 1: Untreated | Extensive Biofilm Growth

Figure 2: HeatX Treatment | No Biofilm Growth

Inspection completed after 180 days of operation determined that there is no visible biological growth on the treated surface, suggesting that the treatment is providing significant resistance to biofouling growth. Additionally, heat transfer efficiency has remained consistent since treated, indicating no degradation in performance. Additional evaluation and inspection will occur at 365 days.

HeatX is an advanced nano-treatment specifically developed for the Oil & Gas industry and optimized for performance under extreme conditions. Learn more about how HeatX can help you with your heat exchange operational needs. Our team looks forward to hearing from you.

Recent Comments